WELCOME TO FANGDA ELECTRIC MACHINE CO..LTD

Understanding Three-Phase Asynchronous Motors: The Backbone of Automotive Electrical Systems

Nov 27,2025

Three-phase asynchronous motors are pivotal in the automotive electrical landscape, particularly in systems that require robust and reliable performance. These motors operate on the principle of electromagnetic induction, utilizing a rotating magnetic field produced by three-phase alternating current. The primary advantage of this design is its efficiency and ability to provide high torque, making

Three-phase asynchronous motors are pivotal in the automotive electrical landscape, particularly in systems that require robust and reliable performance. These motors operate on the principle of electromagnetic induction, utilizing a rotating magnetic field produced by three-phase alternating current. The primary advantage of this design is its efficiency and ability to provide high torque, making it suitable for various automotive applications such as starters, electric pumps, and fans.

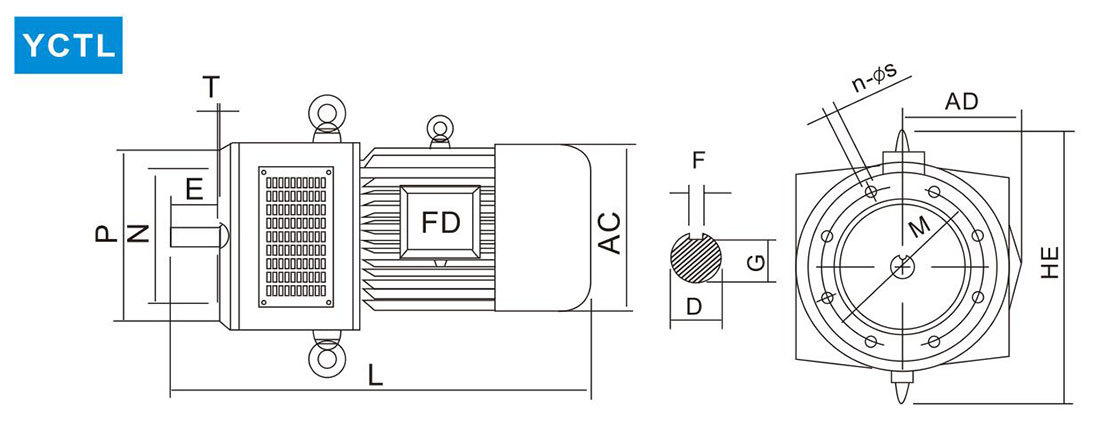

One of the key features of three-phase asynchronous motors is their construction. These motors typically consist of a stator and a rotor. The stator is the stationary part that houses the coils connected to the three-phase power supply. When current passes through these coils, a magnetic field is generated, which induces rotation in the rotor. The rotor—usually squirrel cage or wound—does not have any electrical connections but rotates due to the interaction with the magnetic field created by the stator.

The operation of these motors is characterized by their asynchronous nature, meaning the rotor does not rotate at the same speed as the magnetic field. Instead, there exists a slip, which is the difference between the speed of the magnetic field and the rotor's speed. This slip is essential for the generation of torque. The greater the load on the motor, the higher the slip, which allows the motor to adjust its speed according to the demand.

In the automotive industry, three-phase asynchronous motors offer several advantages. Their robustness and simple construction lead to lower maintenance costs, making them ideal for long-term use in vehicles. Additionally, they exhibit excellent thermal stability and can operate in various environmental conditions, which is crucial for automotive applications subject to fluctuating temperatures and vibrations.

Moreover, these motors are compatible with modern control systems, such as variable frequency drives (VFDs), which enhance their operational efficiency by allowing precise speed control. This capability is increasingly important in vehicles that rely on electrification, enabling better energy management and improving overall vehicle performance.

As automotive technology continues to advance, the integration of three-phase asynchronous motors into electric and hybrid vehicles is becoming more prevalent. Their ability to provide efficient power conversion while maintaining reliability positions them as a critical component in the evolution of automotive electrical systems.

In summary, understanding the workings and benefits of three-phase asynchronous motors is essential for anyone involved in the automotive and electric components industry. Their efficiency, low maintenance, and adaptability to modern technologies make them an invaluable asset in powering various automotive applications, ensuring they remain at the forefront of automotive technology advancements.

One of the key features of three-phase asynchronous motors is their construction. These motors typically consist of a stator and a rotor. The stator is the stationary part that houses the coils connected to the three-phase power supply. When current passes through these coils, a magnetic field is generated, which induces rotation in the rotor. The rotor—usually squirrel cage or wound—does not have any electrical connections but rotates due to the interaction with the magnetic field created by the stator.

The operation of these motors is characterized by their asynchronous nature, meaning the rotor does not rotate at the same speed as the magnetic field. Instead, there exists a slip, which is the difference between the speed of the magnetic field and the rotor's speed. This slip is essential for the generation of torque. The greater the load on the motor, the higher the slip, which allows the motor to adjust its speed according to the demand.

In the automotive industry, three-phase asynchronous motors offer several advantages. Their robustness and simple construction lead to lower maintenance costs, making them ideal for long-term use in vehicles. Additionally, they exhibit excellent thermal stability and can operate in various environmental conditions, which is crucial for automotive applications subject to fluctuating temperatures and vibrations.

Moreover, these motors are compatible with modern control systems, such as variable frequency drives (VFDs), which enhance their operational efficiency by allowing precise speed control. This capability is increasingly important in vehicles that rely on electrification, enabling better energy management and improving overall vehicle performance.

As automotive technology continues to advance, the integration of three-phase asynchronous motors into electric and hybrid vehicles is becoming more prevalent. Their ability to provide efficient power conversion while maintaining reliability positions them as a critical component in the evolution of automotive electrical systems.

In summary, understanding the workings and benefits of three-phase asynchronous motors is essential for anyone involved in the automotive and electric components industry. Their efficiency, low maintenance, and adaptability to modern technologies make them an invaluable asset in powering various automotive applications, ensuring they remain at the forefront of automotive technology advancements.

Contact

E-mail :

Tel/ WhatsApp:

Address:

Daxi Industrial District, Daxi Town, Wenling City, Zhejiang, China