WELCOME TO FANGDA ELECTRIC MACHINE CO..LTD

Understanding Three-Phase Asynchronous Motors: A Guide for Professionals

Jan 10,2026

Three-phase asynchronous motors, also known as induction motors, are widely used in various industrial applications due to their efficiency and robustness. These motors operate on the principle of electromagnetic induction, where the rotor is induced to rotate by the rotating magnetic field produced by the stator. Unlike synchronous motors, asynchronous motors do not require an external power sour

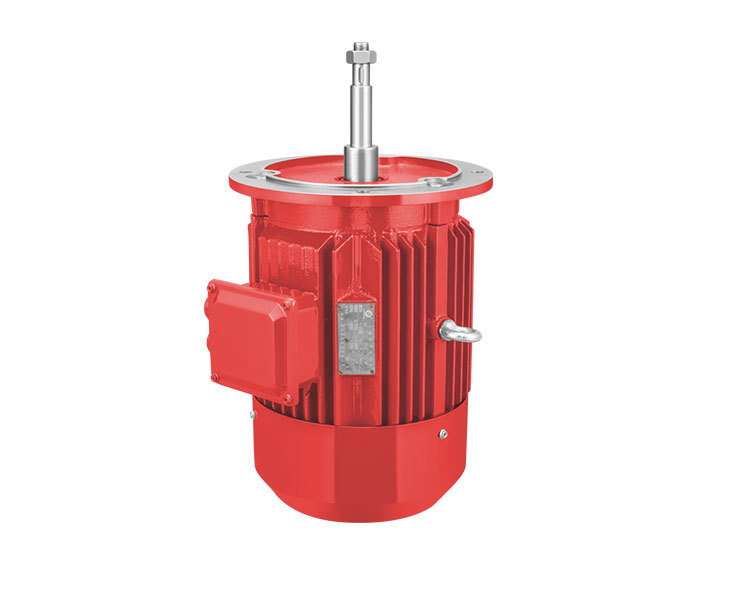

Three-phase asynchronous motors, also known as induction motors, are widely used in various industrial applications due to their efficiency and robustness. These motors operate on the principle of electromagnetic induction, where the rotor is induced to rotate by the rotating magnetic field produced by the stator. Unlike synchronous motors, asynchronous motors do not require an external power source for the rotor; instead, they rely on the slip between the rotor's speed and the stator's magnetic field to generate torque.

One of the key features of three-phase asynchronous motors is their ability to maintain a relatively constant speed under varying loads. This characteristic makes them particularly suitable for applications where consistent performance is essential, such as in pumps, fans, and conveyor systems. The three-phase design allows for a more balanced load distribution, resulting in reduced vibrations and smoother operation compared to single-phase motors.

In terms of construction, three-phase asynchronous motors consist of two main components: the stator and the rotor. The stator is the stationary part of the motor, containing windings that create the rotating magnetic field when three-phase alternating current is applied. The rotor, typically made of conductive materials like aluminum or copper, is located inside the stator and is free to rotate. The interaction between the stator's magnetic field and the rotor induces current in the rotor, which produces the necessary torque for rotation.

The advantages of using three-phase asynchronous motors include lower maintenance requirements, higher efficiency, and a more straightforward construction compared to other motor types. Additionally, they are capable of handling large loads, making them ideal for heavy-duty applications. Their robustness also means they can operate in harsh environments, which is crucial for many industries.

However, it is important to note that while three-phase asynchronous motors are highly efficient, they can exhibit reduced efficiency at low loads. This is a consideration for applications that may require varying operational levels. Additionally, the starting torque of these motors is generally lower than that of synchronous motors, which may necessitate the use of external starting mechanisms in certain scenarios.

In conclusion, three-phase asynchronous motors play a vital role in today's industrial landscape, offering reliable performance and versatility across numerous applications. Understanding their operational principles, advantages, and potential limitations can empower professionals in the electrical engineering field to make informed decisions regarding motor selection and utilization in power generation and electrical systems.

One of the key features of three-phase asynchronous motors is their ability to maintain a relatively constant speed under varying loads. This characteristic makes them particularly suitable for applications where consistent performance is essential, such as in pumps, fans, and conveyor systems. The three-phase design allows for a more balanced load distribution, resulting in reduced vibrations and smoother operation compared to single-phase motors.

In terms of construction, three-phase asynchronous motors consist of two main components: the stator and the rotor. The stator is the stationary part of the motor, containing windings that create the rotating magnetic field when three-phase alternating current is applied. The rotor, typically made of conductive materials like aluminum or copper, is located inside the stator and is free to rotate. The interaction between the stator's magnetic field and the rotor induces current in the rotor, which produces the necessary torque for rotation.

The advantages of using three-phase asynchronous motors include lower maintenance requirements, higher efficiency, and a more straightforward construction compared to other motor types. Additionally, they are capable of handling large loads, making them ideal for heavy-duty applications. Their robustness also means they can operate in harsh environments, which is crucial for many industries.

However, it is important to note that while three-phase asynchronous motors are highly efficient, they can exhibit reduced efficiency at low loads. This is a consideration for applications that may require varying operational levels. Additionally, the starting torque of these motors is generally lower than that of synchronous motors, which may necessitate the use of external starting mechanisms in certain scenarios.

In conclusion, three-phase asynchronous motors play a vital role in today's industrial landscape, offering reliable performance and versatility across numerous applications. Understanding their operational principles, advantages, and potential limitations can empower professionals in the electrical engineering field to make informed decisions regarding motor selection and utilization in power generation and electrical systems.

PREVIOUS:

Contact

E-mail :

Tel/ WhatsApp:

Address:

Daxi Industrial District, Daxi Town, Wenling City, Zhejiang, China