WELCOME TO FANGDA ELECTRIC MACHINE CO..LTD

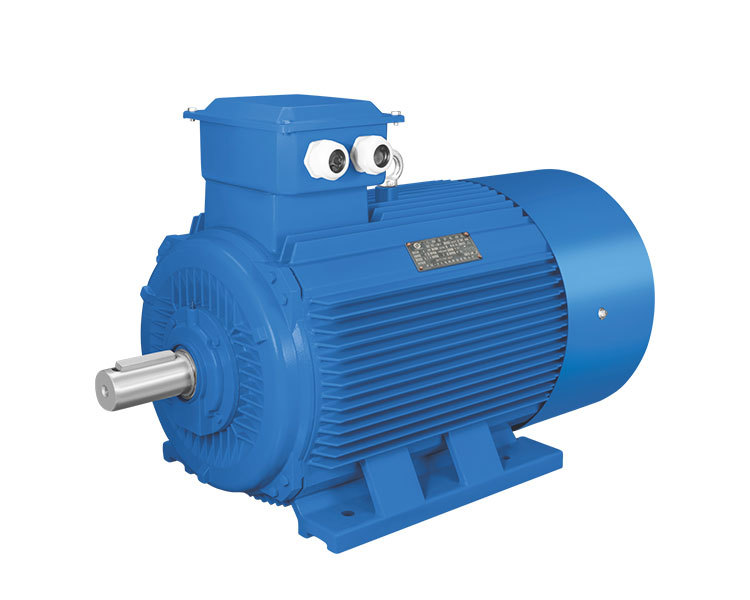

Understanding Three-Phase Asynchronous Motors: A Key Component in Electrical Engineering

Dec 18,2025

The three-phase asynchronous motor, commonly referred to as an induction motor, operates on the principles of electromagnetic induction. It consists of two main components: the stator and the rotor. The stator is the stationary part, which generates a rotating magnetic field when three-phase alternating current flows through its windings. The rotor, placed within this magnetic field, experiences i

The three-phase asynchronous motor, commonly referred to as an induction motor, operates on the principles of electromagnetic induction. It consists of two main components: the stator and the rotor. The stator is the stationary part, which generates a rotating magnetic field when three-phase alternating current flows through its windings. The rotor, placed within this magnetic field, experiences induced currents that create a magnetic field of its own, allowing it to rotate and produce mechanical work.

One of the primary advantages of three-phase asynchronous motors is their efficiency. They are designed to run smoothly and efficiently, making them suitable for a wide range of applications. These motors can handle varying loads without significant loss of performance, making them ideal for industrial environments where operational demands can fluctuate. Additionally, they require less maintenance compared to their synchronous counterparts, as they do not need external excitation.

Three-phase asynchronous motors are widely used in various industries, from manufacturing and pumping to HVAC and conveyor systems. Their robustness and reliability make them an excellent choice for high-demand applications. Moreover, these motors can be easily controlled through variable frequency drives (VFDs), allowing for precise speed regulation and energy savings.

In terms of performance, the synchronous speed of a three-phase asynchronous motor is determined by the frequency of the supply current and the number of poles in the motor. It is important to note that the rotor will always rotate at a speed lower than the synchronous speed, providing a slip that is essential for torque generation. The amount of slip varies with the load; higher loads will result in a greater slip.

Safety is another crucial aspect when dealing with three-phase asynchronous motors. They are built with various protective features, such as thermal overload protection, to prevent damage due to overheating. Additionally, proper installation and regular maintenance are vital to ensure optimal performance and longevity.

In summary, the three-phase asynchronous motor plays a crucial role in electrical engineering and power generation equipment. Its efficiency, versatility, and minimal maintenance requirements make it a preferred choice for numerous applications. As technology advances, these motors continue to evolve, offering improved performance and energy efficiency, solidifying their place as essential components in the industrial landscape. Understanding their operational characteristics and benefits is key for anyone involved in electrical engineering and power generation.

One of the primary advantages of three-phase asynchronous motors is their efficiency. They are designed to run smoothly and efficiently, making them suitable for a wide range of applications. These motors can handle varying loads without significant loss of performance, making them ideal for industrial environments where operational demands can fluctuate. Additionally, they require less maintenance compared to their synchronous counterparts, as they do not need external excitation.

Three-phase asynchronous motors are widely used in various industries, from manufacturing and pumping to HVAC and conveyor systems. Their robustness and reliability make them an excellent choice for high-demand applications. Moreover, these motors can be easily controlled through variable frequency drives (VFDs), allowing for precise speed regulation and energy savings.

In terms of performance, the synchronous speed of a three-phase asynchronous motor is determined by the frequency of the supply current and the number of poles in the motor. It is important to note that the rotor will always rotate at a speed lower than the synchronous speed, providing a slip that is essential for torque generation. The amount of slip varies with the load; higher loads will result in a greater slip.

Safety is another crucial aspect when dealing with three-phase asynchronous motors. They are built with various protective features, such as thermal overload protection, to prevent damage due to overheating. Additionally, proper installation and regular maintenance are vital to ensure optimal performance and longevity.

In summary, the three-phase asynchronous motor plays a crucial role in electrical engineering and power generation equipment. Its efficiency, versatility, and minimal maintenance requirements make it a preferred choice for numerous applications. As technology advances, these motors continue to evolve, offering improved performance and energy efficiency, solidifying their place as essential components in the industrial landscape. Understanding their operational characteristics and benefits is key for anyone involved in electrical engineering and power generation.

Contact

E-mail :

Tel/ WhatsApp:

Address:

Daxi Industrial District, Daxi Town, Wenling City, Zhejiang, China